1

Enterprise Risk Management

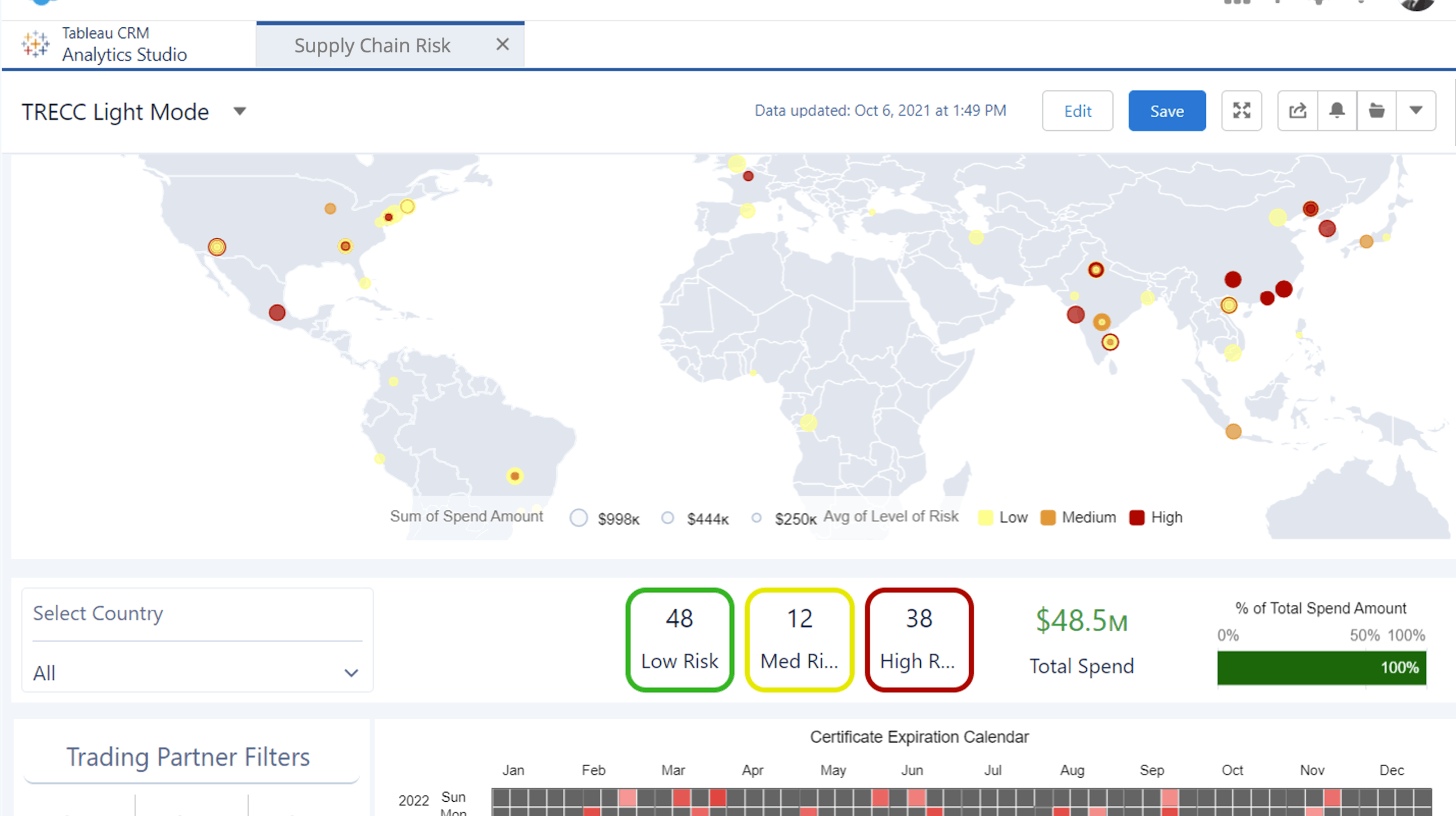

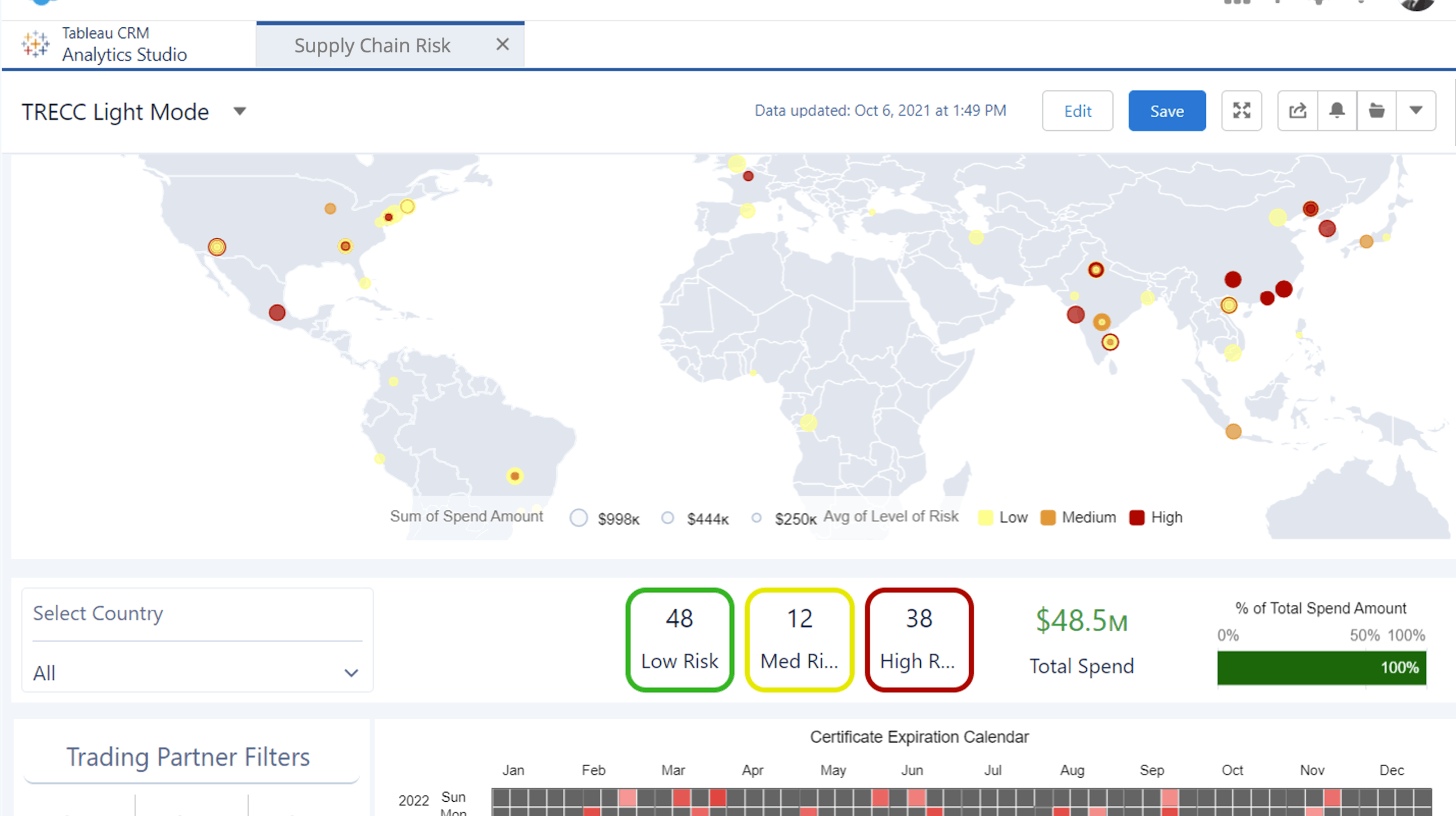

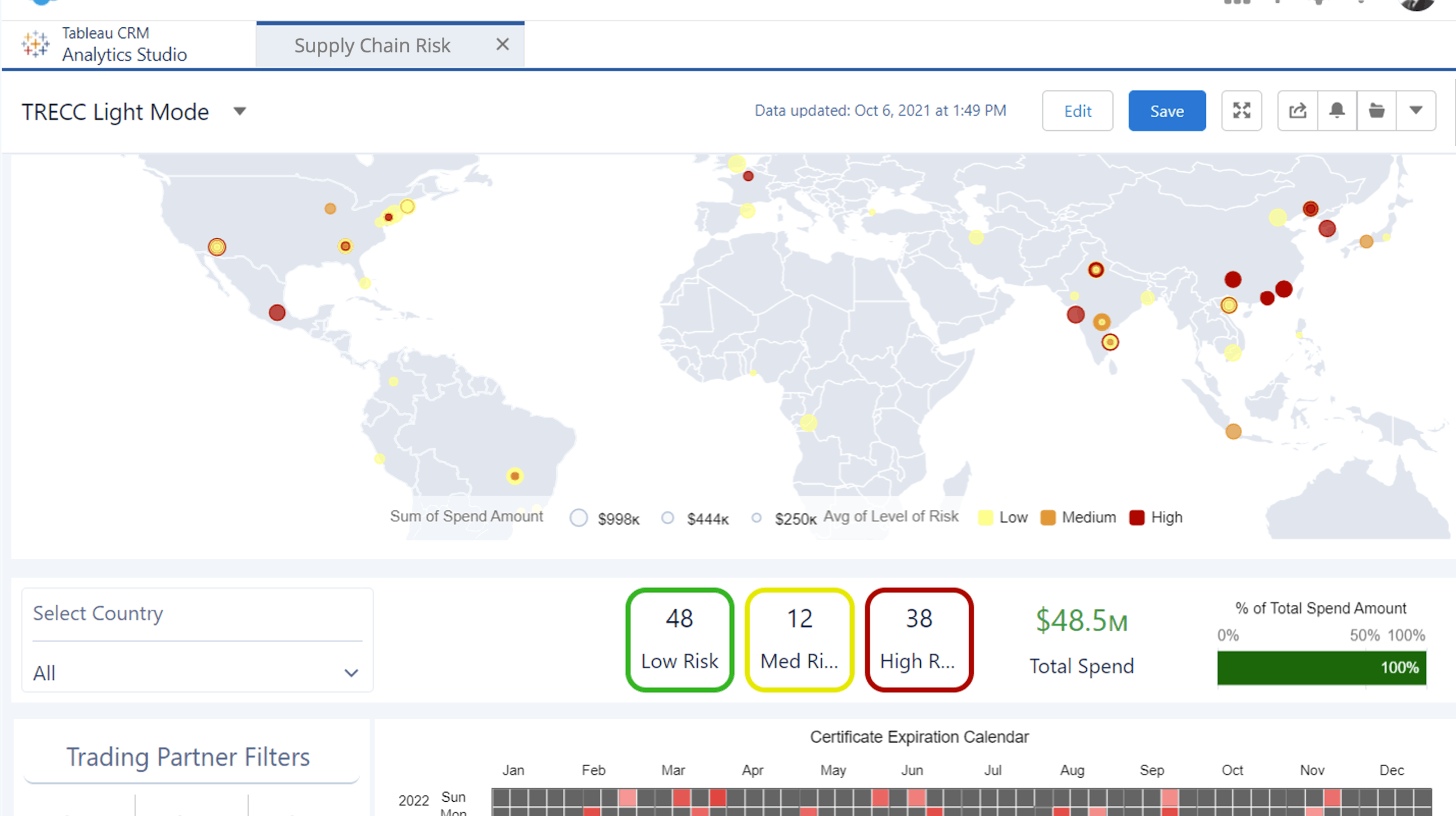

Sourcing managers, project managers, and other employees across the organization can anticipate, assess, mitigate, and monitor various forms of risk to your organization. Dashboards, as seen below, help expose risk factors by combining and surfacing relevant information from various data sources across the enterprise. By connecting risks with other relevant data, the relationships and cumulative impact are better understood.

This dashboard combines spend amounts with risk levels, locations, supplier tier, and compliance certifications to comprehensively represent the enterprise risk profile. However, as each element is further explored, flexible processes and actions can be taken directly from the insights that are revealed.

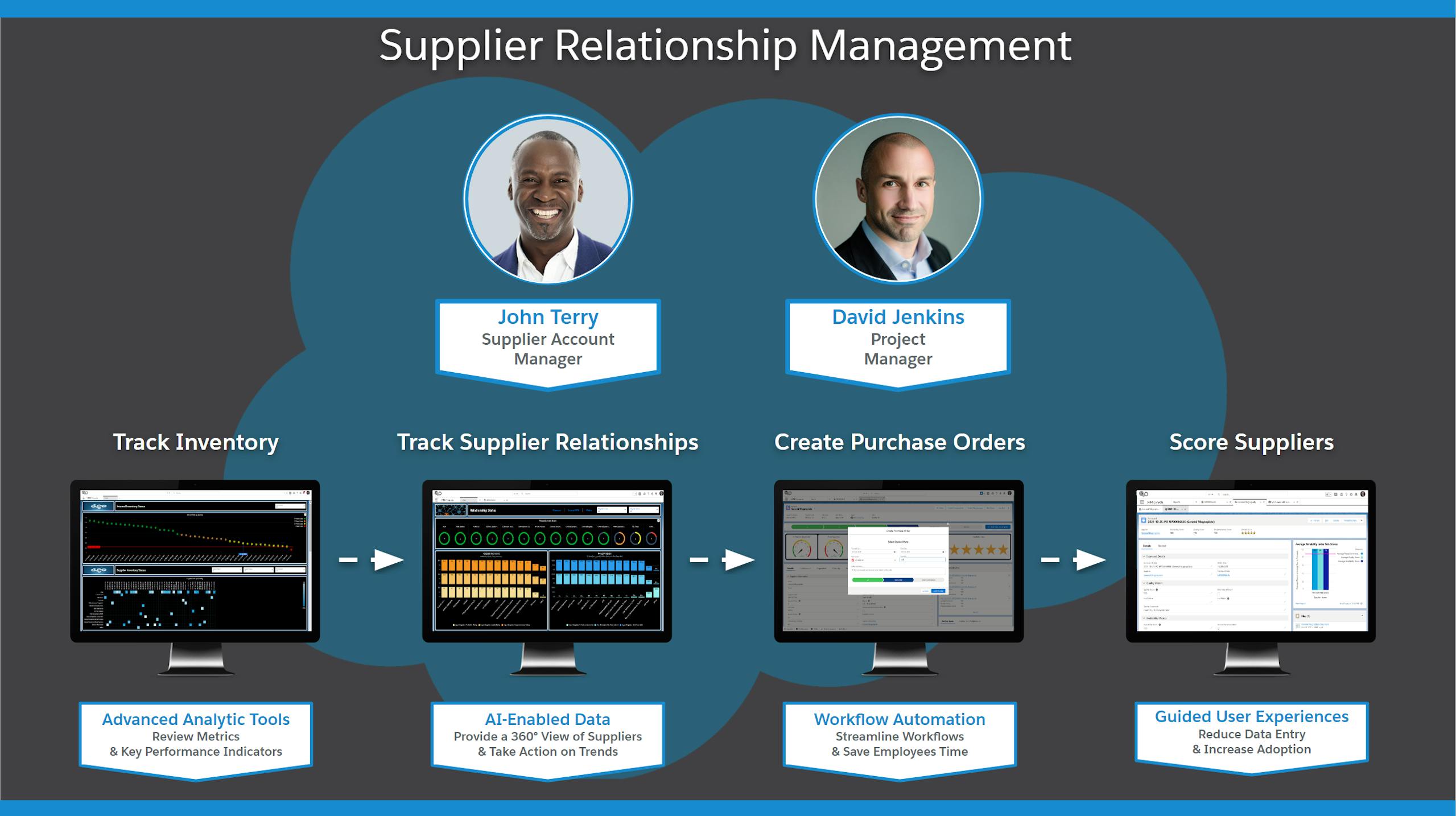

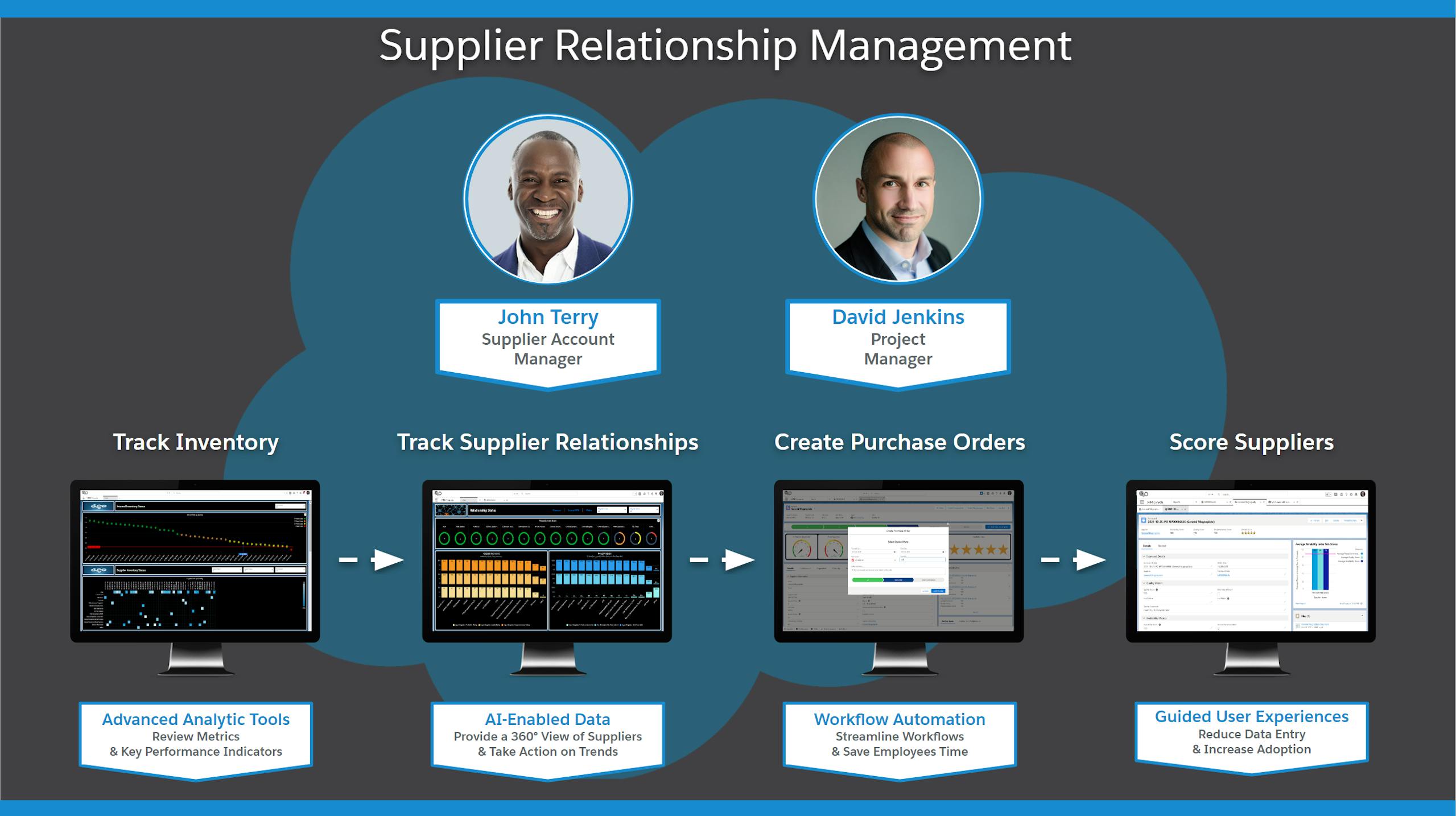

End-to-End Supplier Relationship Management

Organizations often face challenges viewing and interacting with their supplier data due to siloed information systems, and legacy file management systems with limited search and collaboration features.

The Salesforce platform provides a flexible no-code approach to these challenges by providing a 360-degree view of an organization's supply inventory via advanced data analytics, artificial intelligence, and an open API architecture enabling data integration with vendor inventory systems.

Supply chain stakeholders can easily create fully-immersive dashboards summarizing their key performance indicators with an easy-to-use drag and drop interface and intuitive menus.

Meet John, a Supplier Account Manager

John is a Supplier Account Manager whose organization recently adopted Salesforce and implemented a new Supplier Relationship Management application. John’s organization previously used a solution to manage supplier relationships that relied heavily upon multiple stovepipe systems and spreadsheets. This solution required hours of manual data entry and hours of analysis to identify actionable insights.

John is excited to use the Salesforce platform to get a 360-degree view of his organization’s supply inventory as well as gauge the health of their relationships with the key suppliers in their value chain.

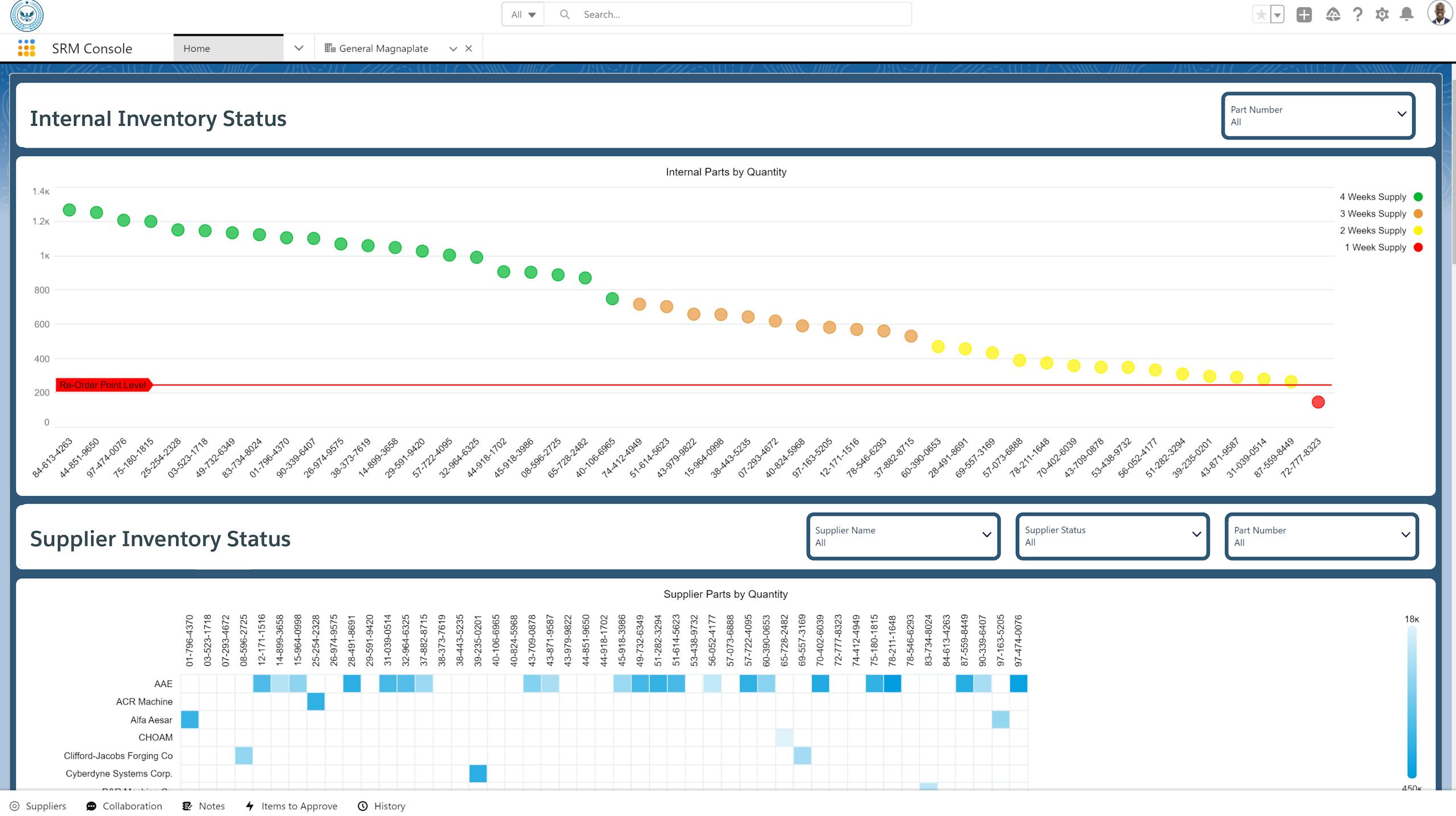

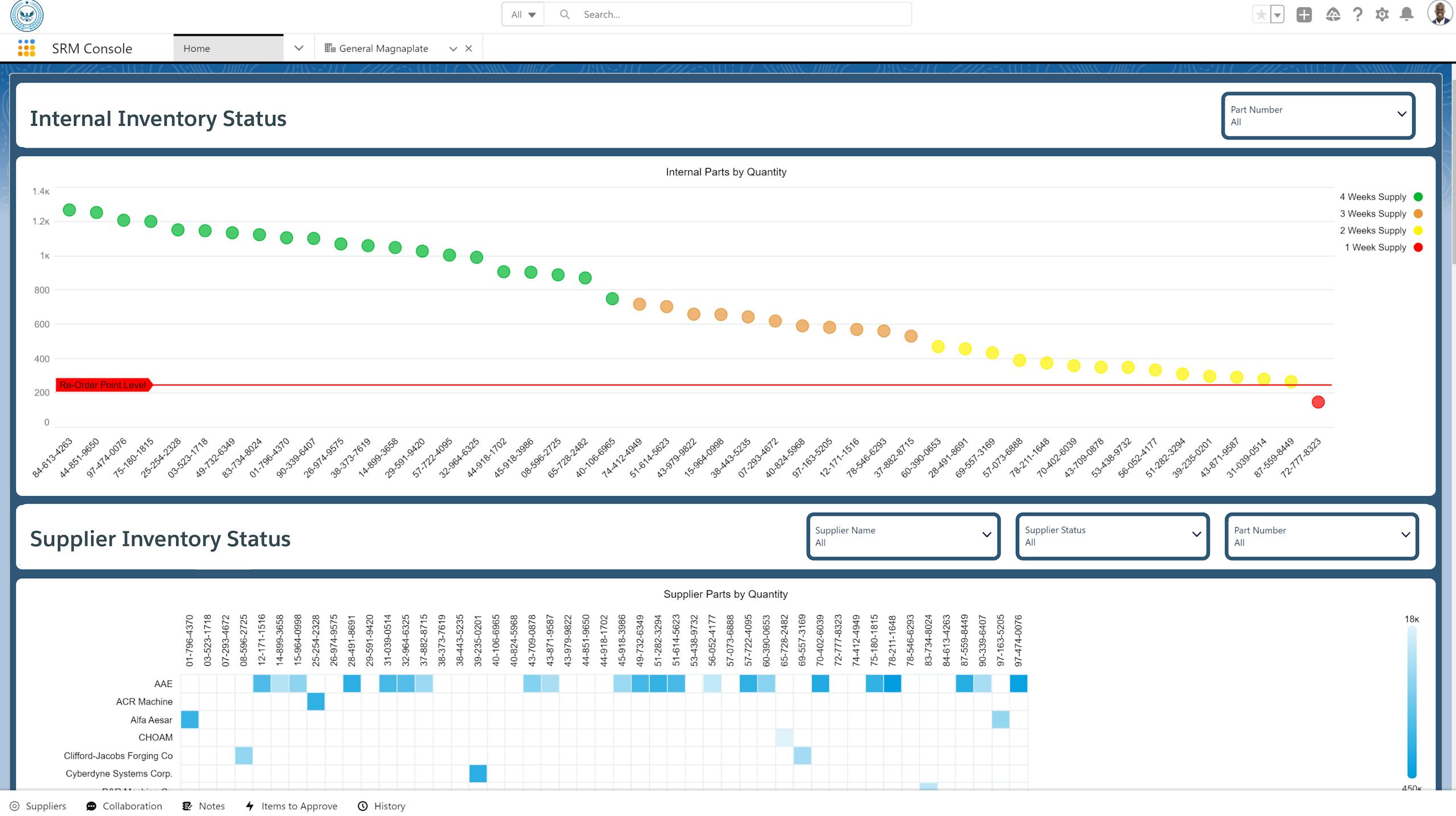

John begins his day on the Supplier Relationship Management (SRM) app’s homepage, checking inventory levels on common-use parts to ensure an adequate supply.

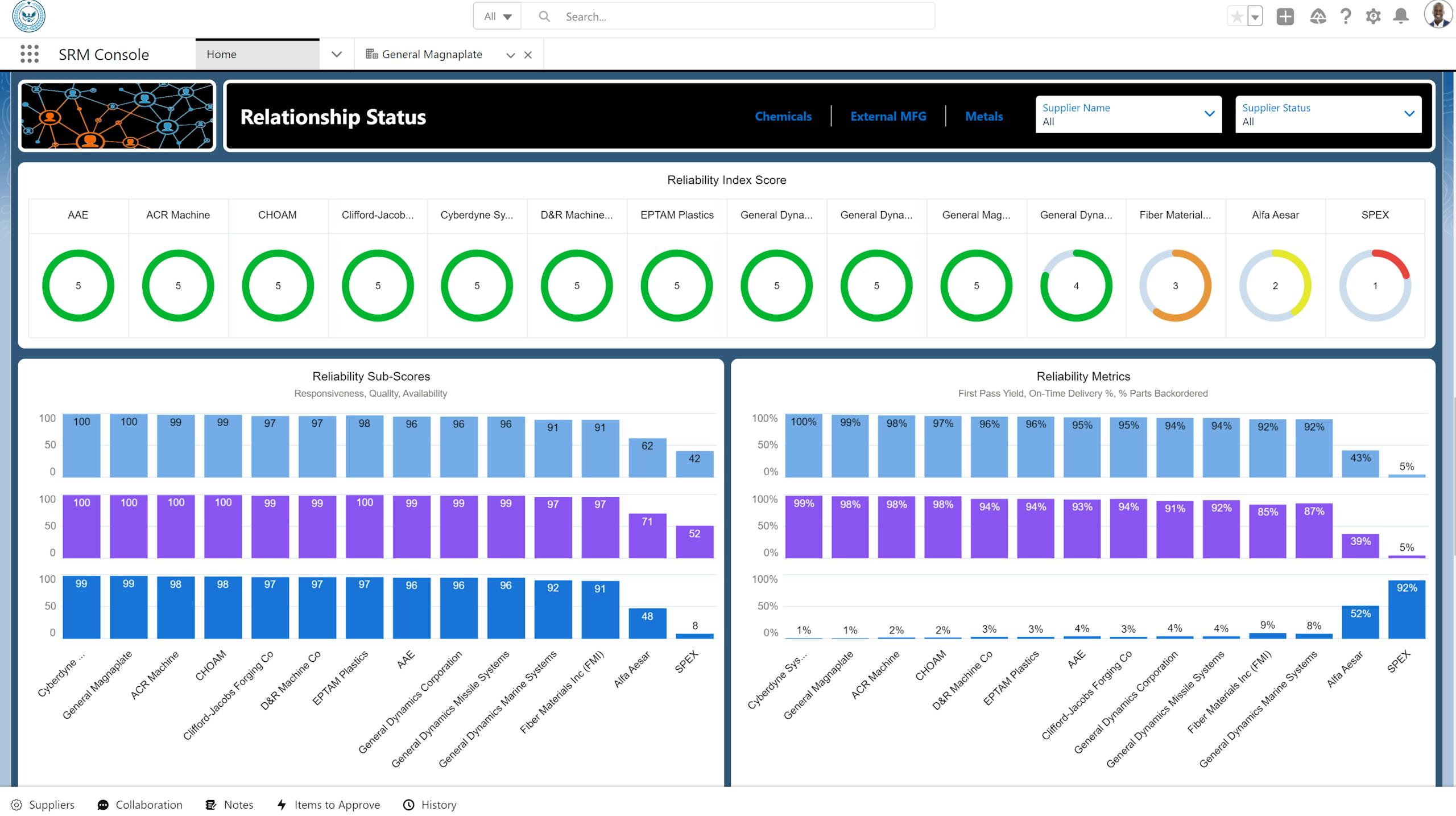

Visualize Relationship Management Metrics

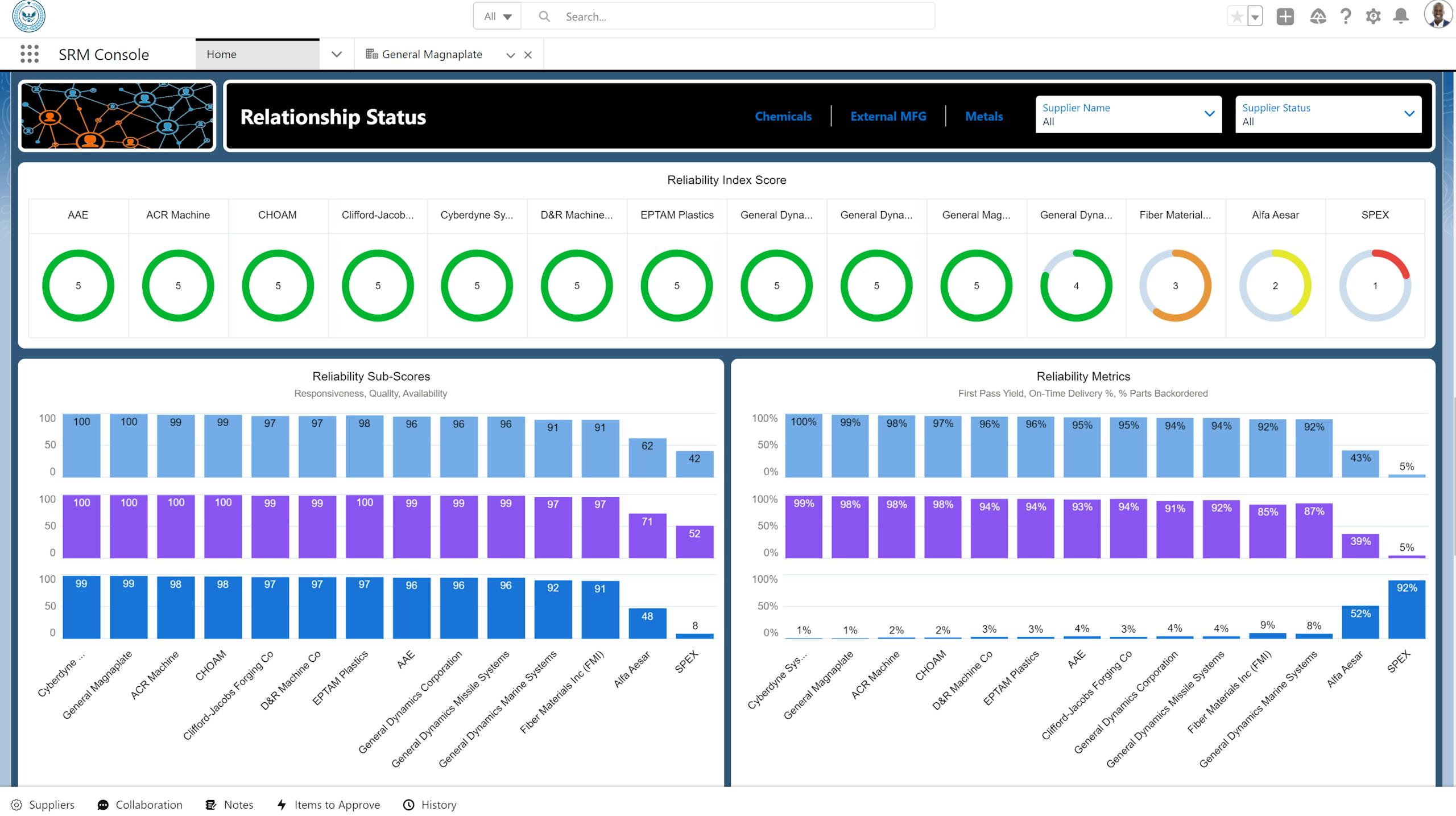

The Relationship Status section of the SRM dashboard provides John with a detailed overview of the reliability of all suppliers in his value chain. Dynamic filters drill down to specific vendors and individual reliability factors, enabling John to make data-driven decisions for sourcing future parts orders while limiting risk.

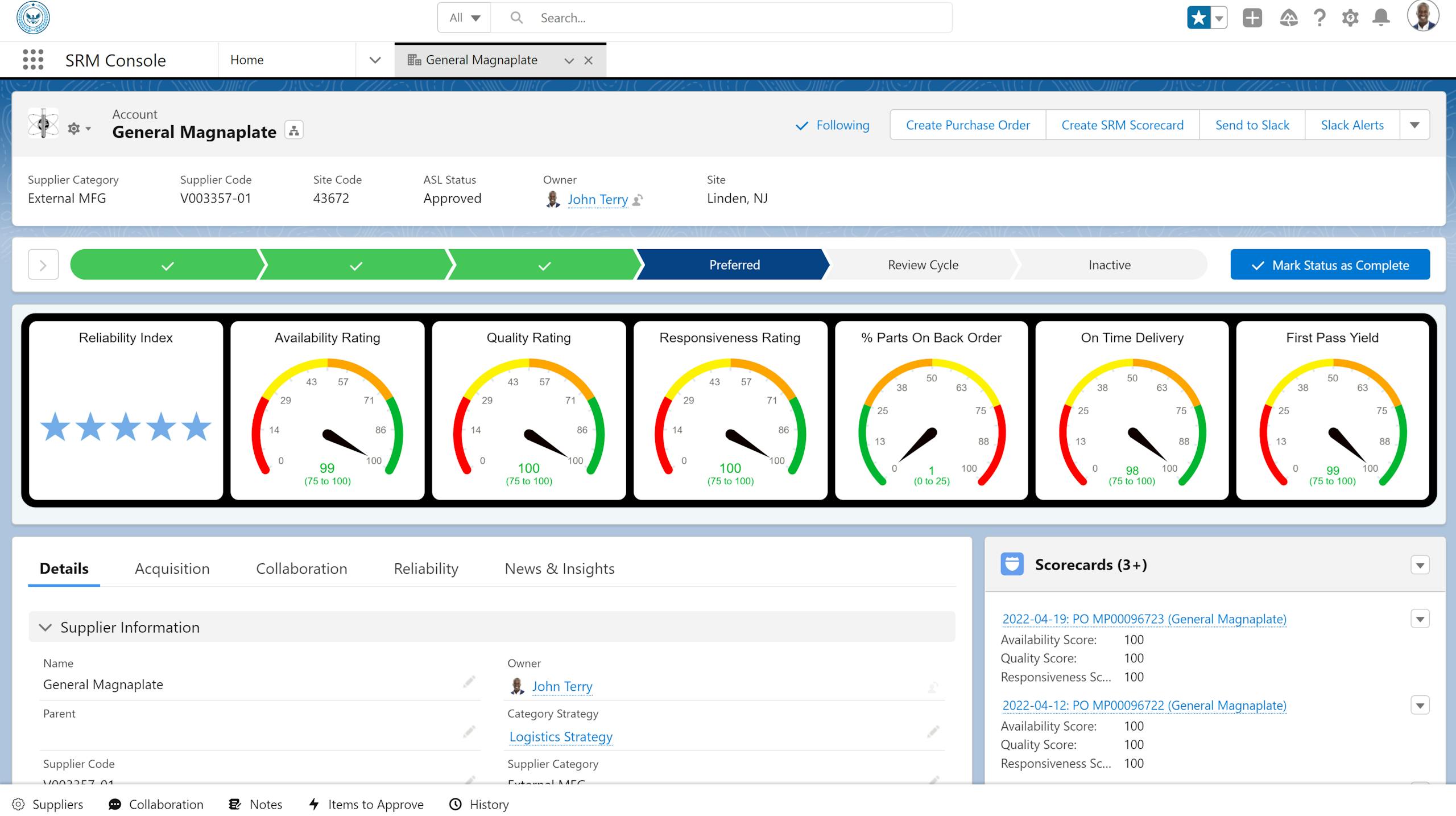

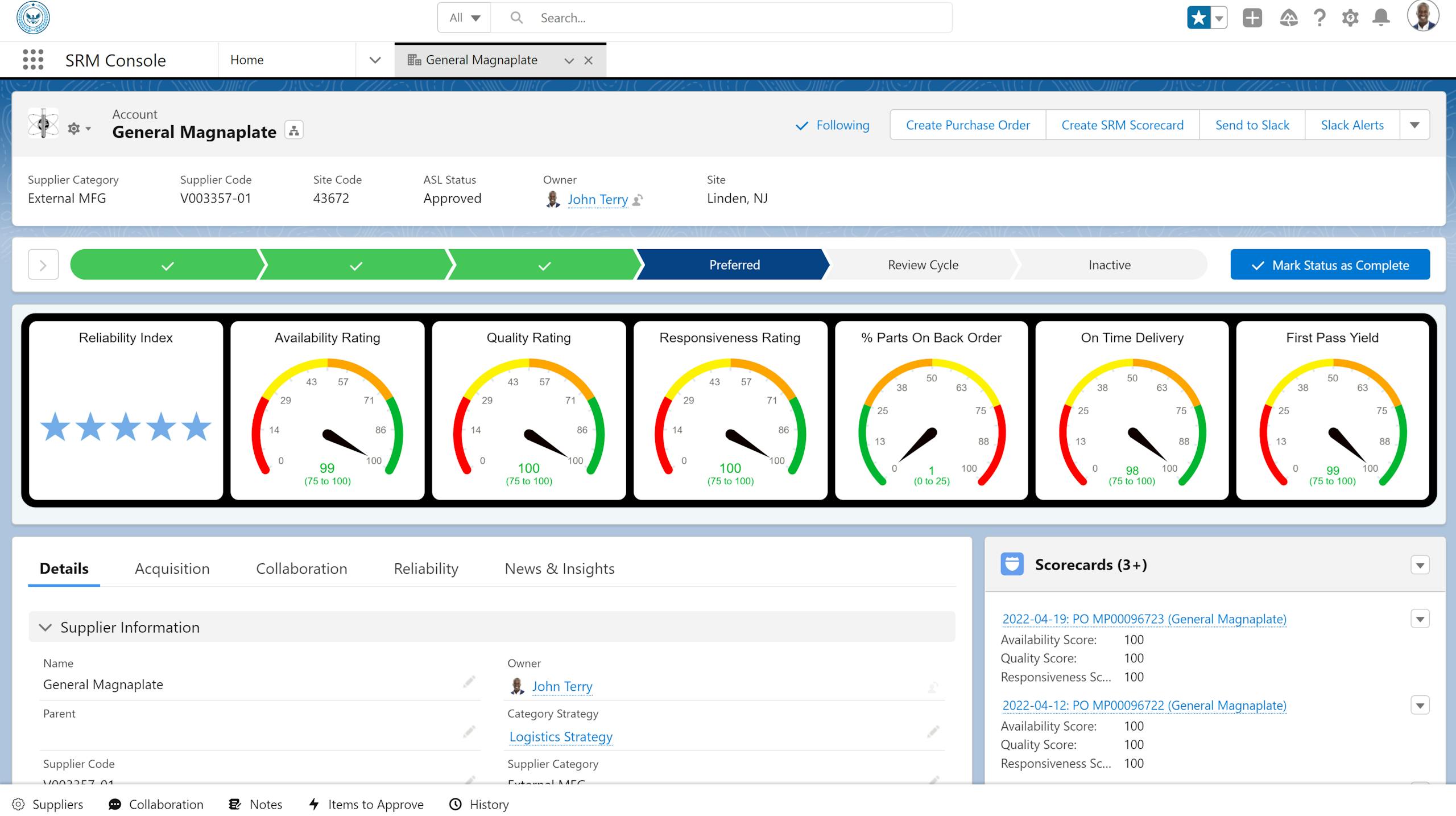

Supplier Account Information at a Glance

John’s organization previously used disparate data systems and legacy applications with high levels of technical debt requiring frequent code patching and updates. Salesforce acts as an engagement layer, unifying siloed data through configurable low-code integration tools while providing process automation and artificial intelligence features.

Here, John can see unified data on the supplier account General Magnaplate and uses these features to dramatically reduce manual effort and aid in his decision-making. Based on General Magnaplate’s reliability index, John decides to place an order.

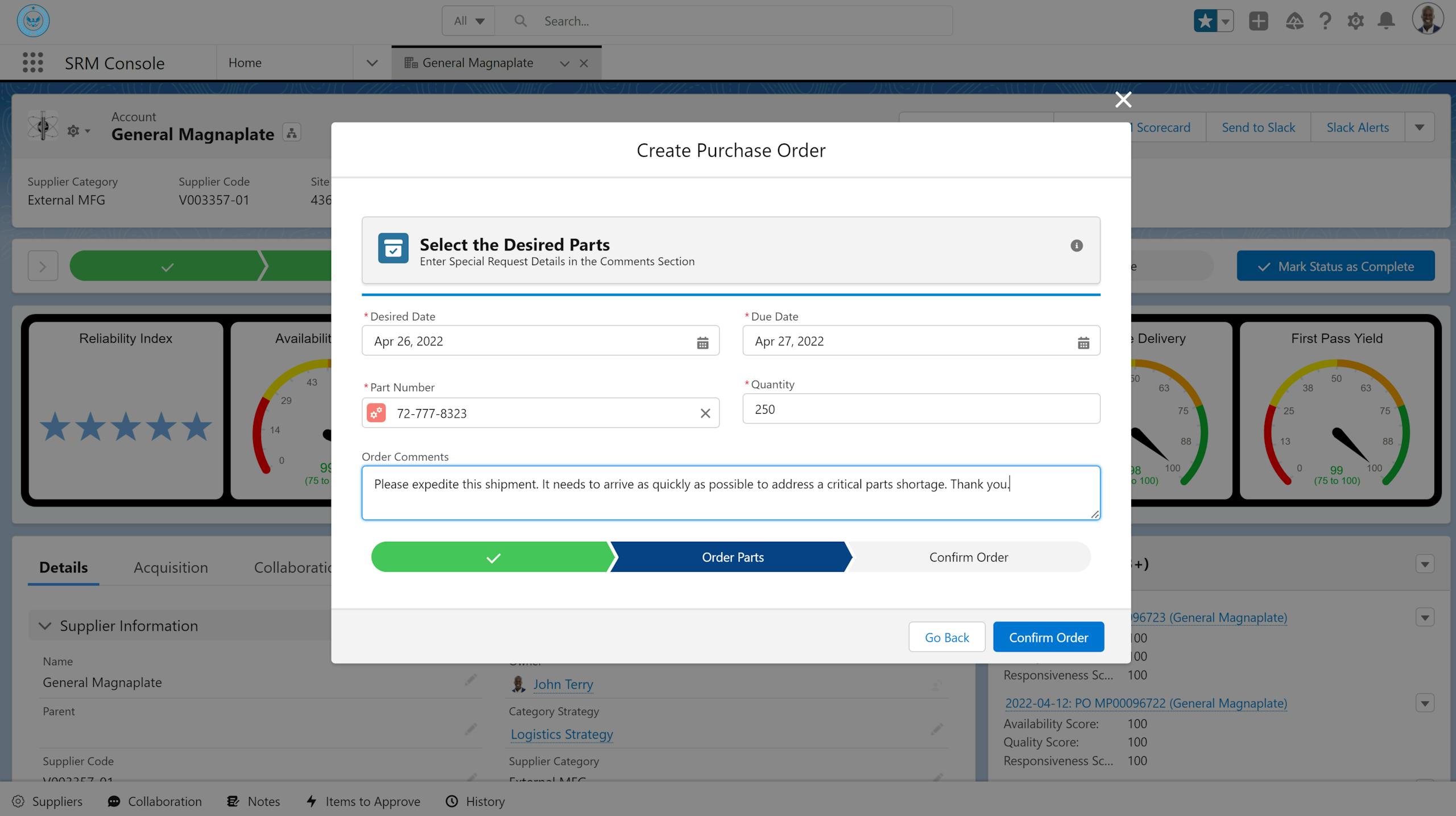

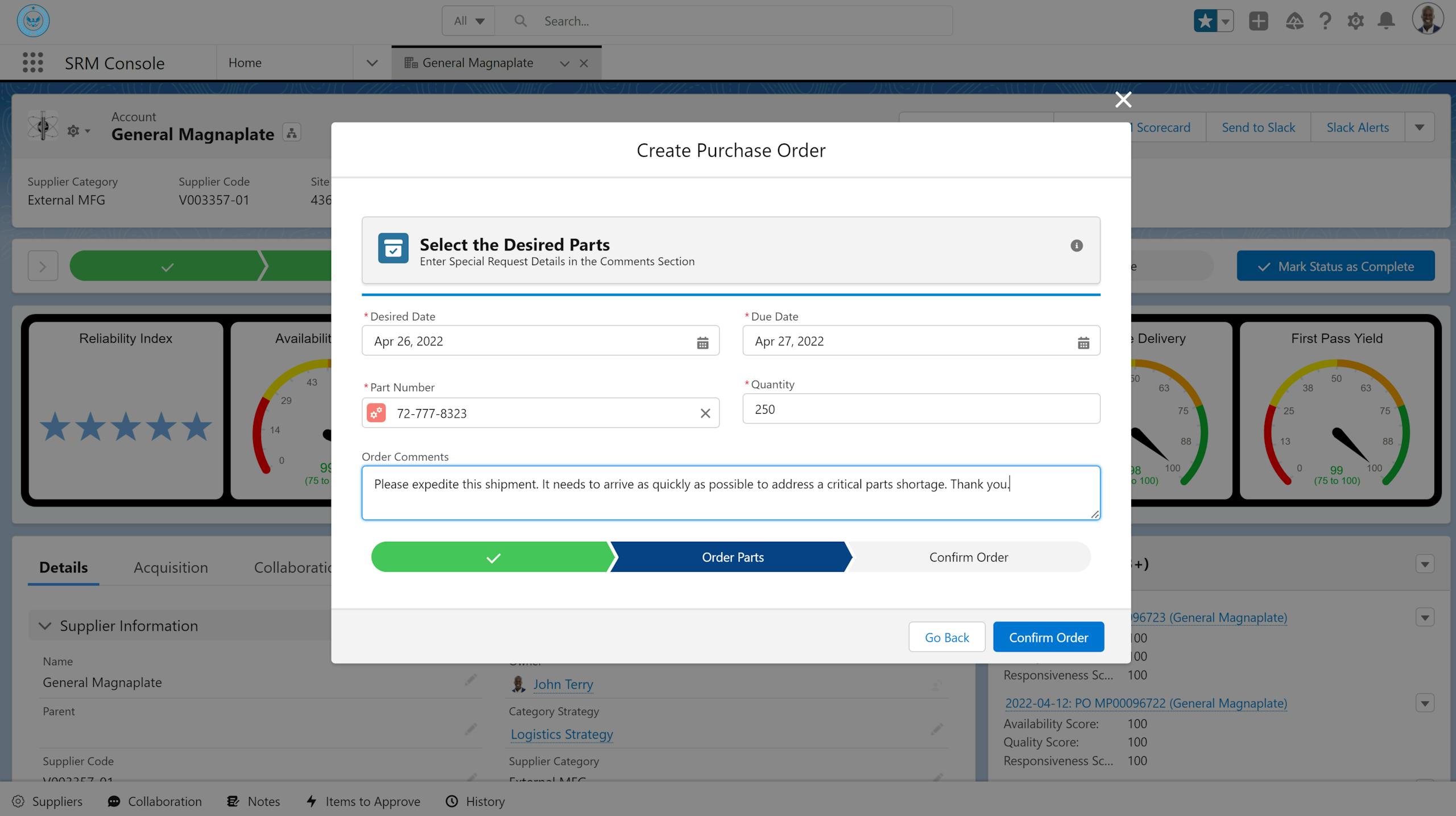

Easily Create Purchase Orders with No-Code Process Automation Tools

John’s organization was able to create a guided user experience workflow in minutes using a no-code process automation tool, minimizing manual data entry and guiding John through the purchase order process.

John selects General Magnaplate to fill a gap in his inventory and quickly and easily create a purchase order without needing to log into his ERP system. Salesforce serves as the engagement layer for John’s organization, surfacing all of its supply, purchasing, and financial information in a secure interface, providing a 360-degree view of their data.

To get started, John clicks the “Create Purchase Order” button in his highlights panel.

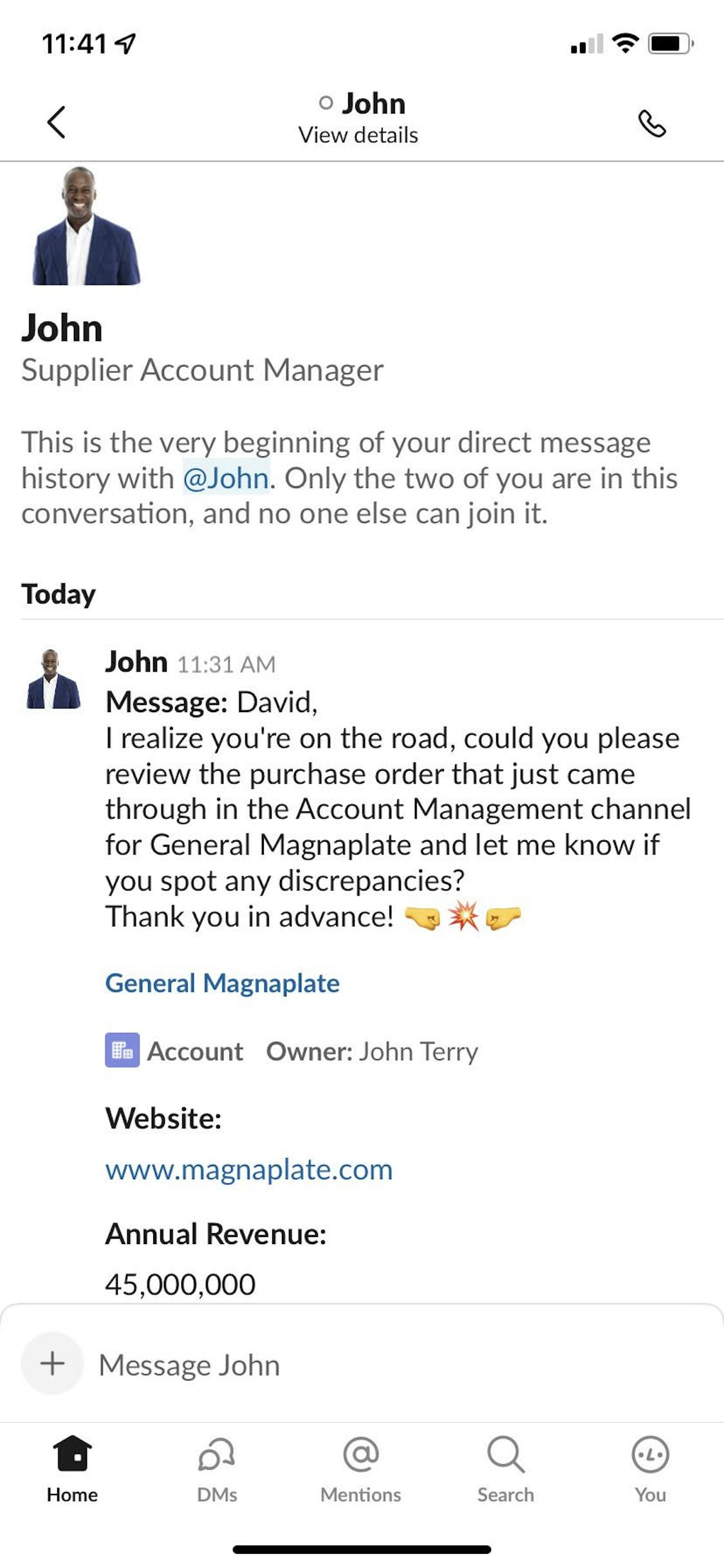

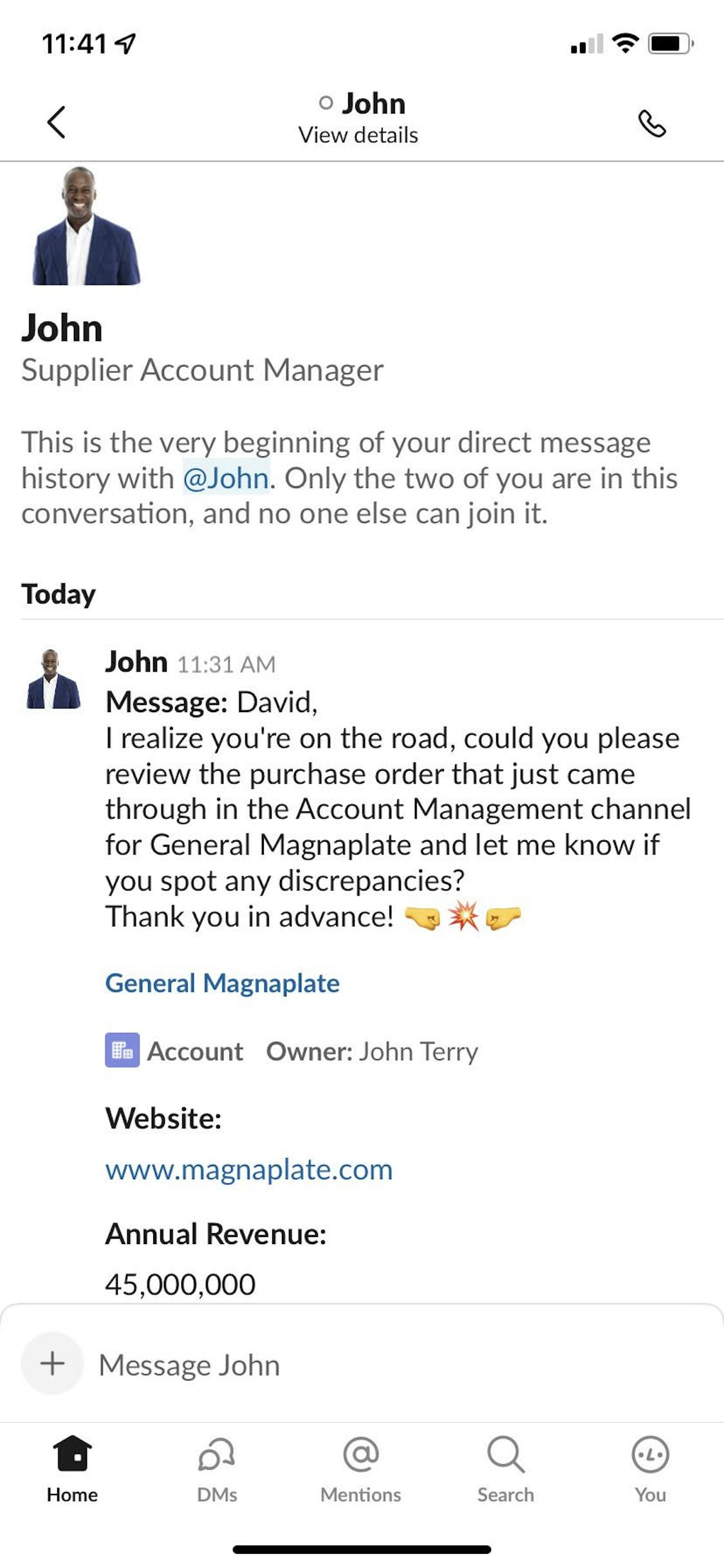

Enable Mobile Collaboration with Slack

John uses Slack to collaborate with his program manager, David, who is often on the road and working from his mobile device. Once John submits the purchase order, David receives an instant notification directly in slack in his account management channel, with a message from John to review it.

David can respond to John’s message, view the purchase order details, and access the record in Salesforce from within Slack - all thanks to an integration that was set up in minutes with clicks, not code.

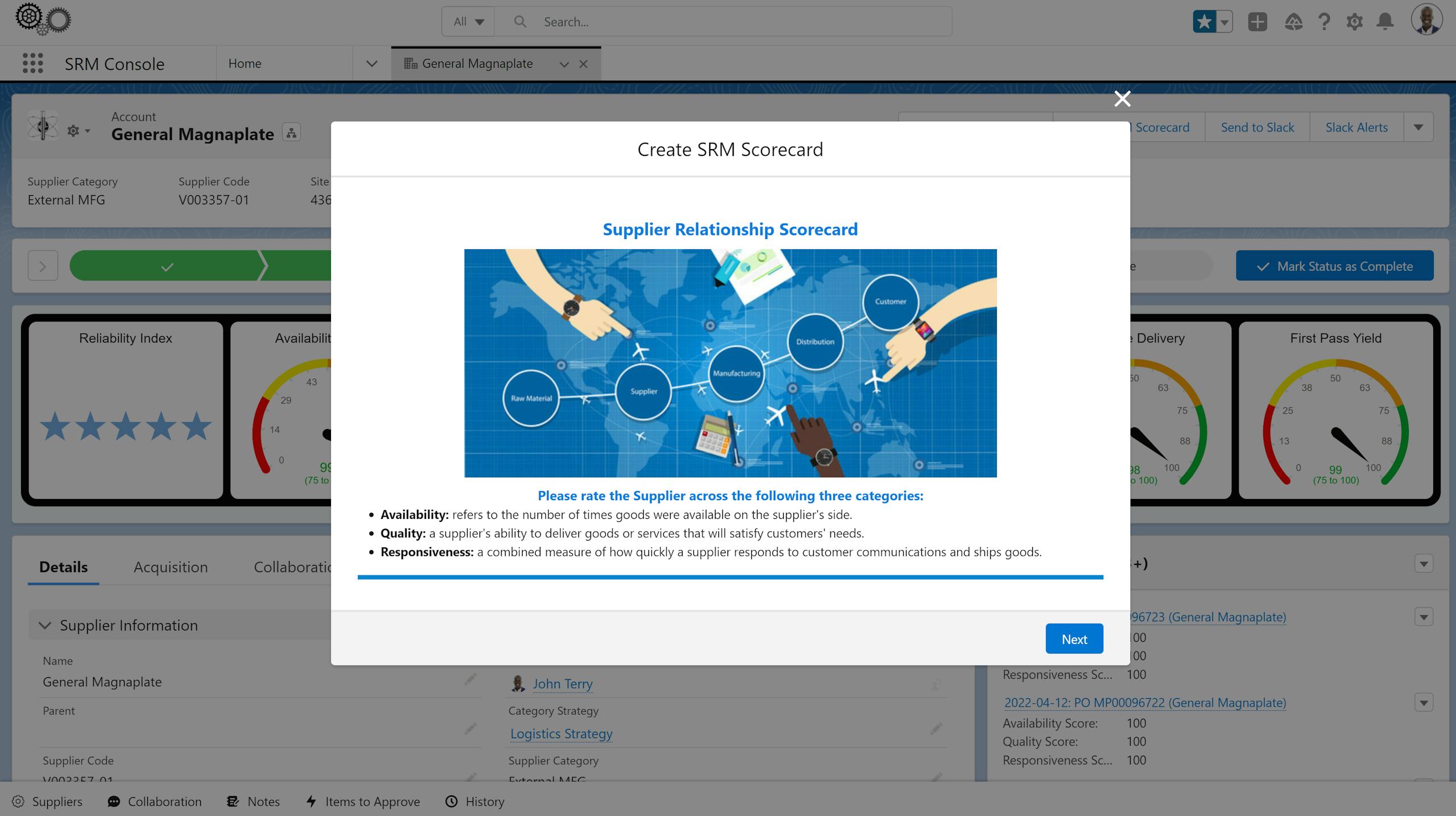

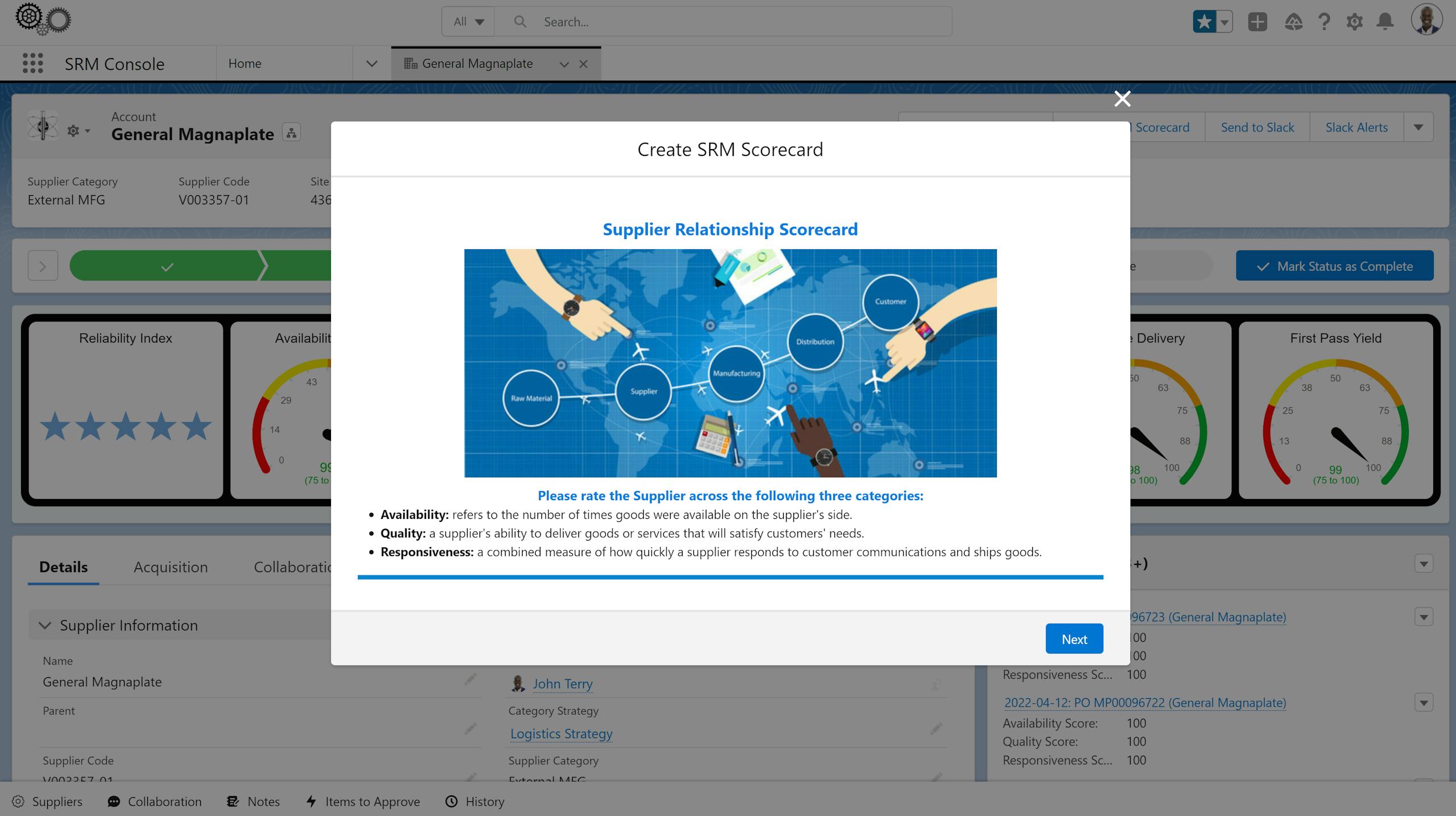

Guided Scorecard Creation

After the arrival of the parts shipment, John uses a guided experience user tool to score the supplier across key reliability impact areas, enriching the scorecard database and providing actionable to inform the supplier relationship selection process - all from within the Salesforce Platform. These scorecard metrics are surfaced in intuitive analytic dashboards, providing actionable data for informing supplier selection and purchasing decisions while limiting risk.

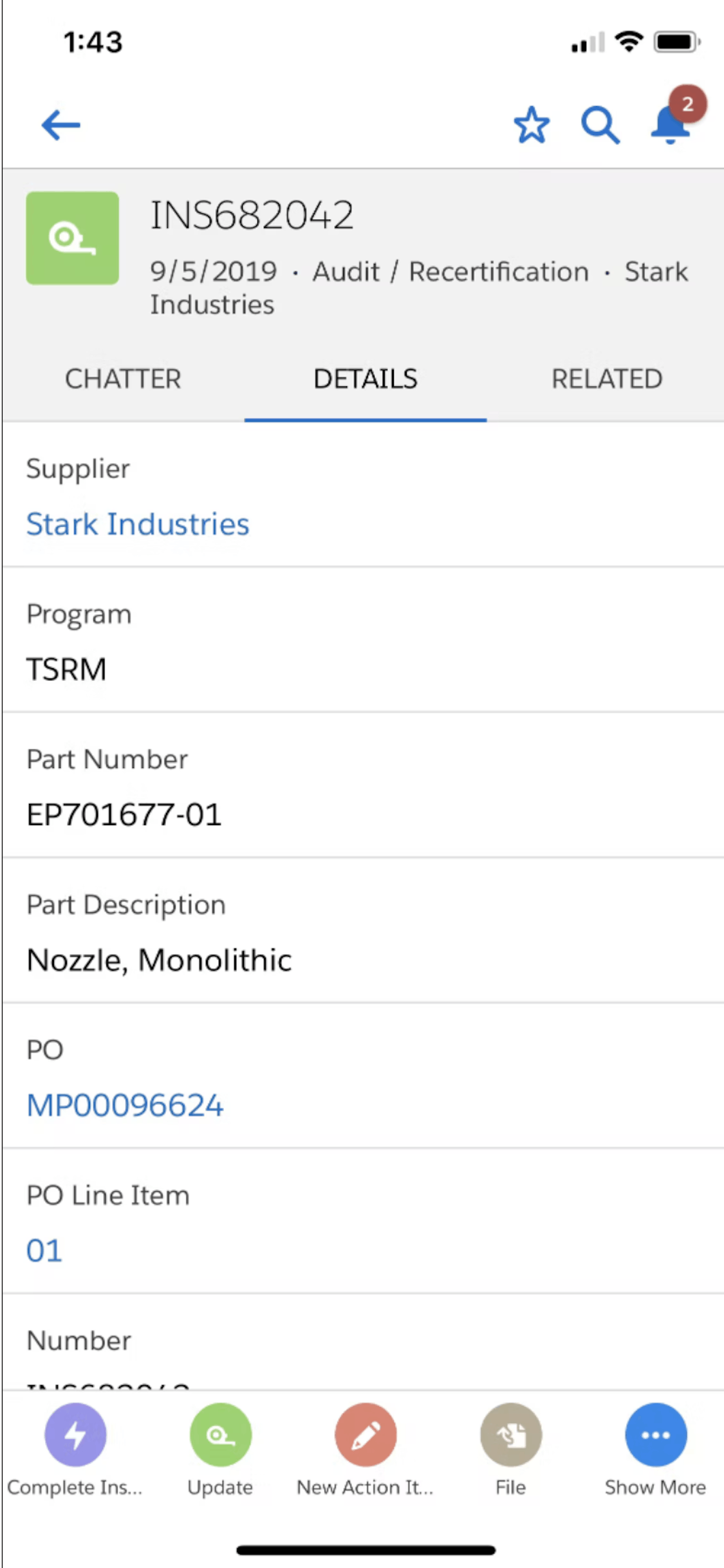

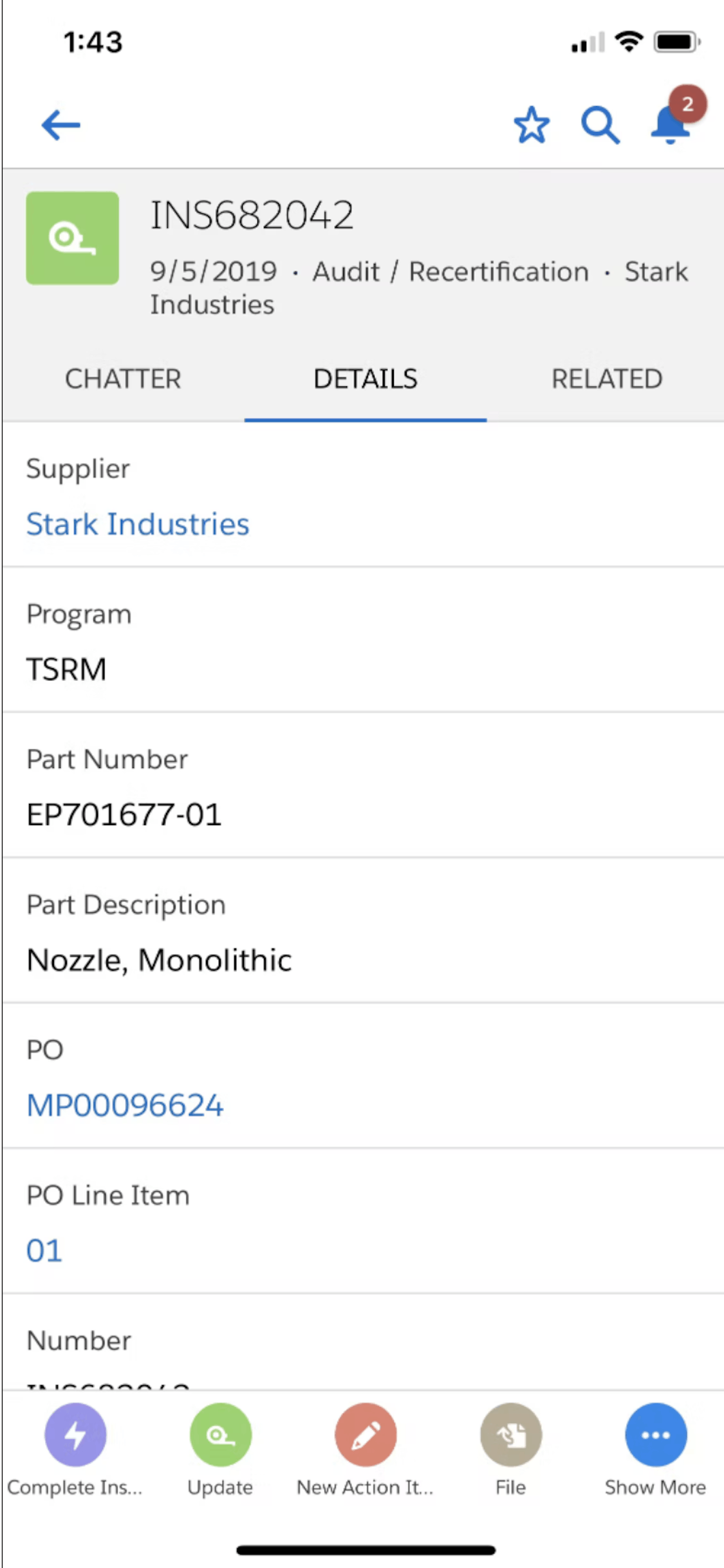

Access Supplier Account Insight On the Go

Salesforce Mobile puts the power of the Salesforce platform in John and David’s hands while on the go. They’re able to access supplier account details, contacts, open action items, and related activity history. Supplier inspections and audits are now much more efficient via the mobile application, which provides collaboration, image file uploading, navigation, and even voice-to-text for instantaneous updates to the inspection.

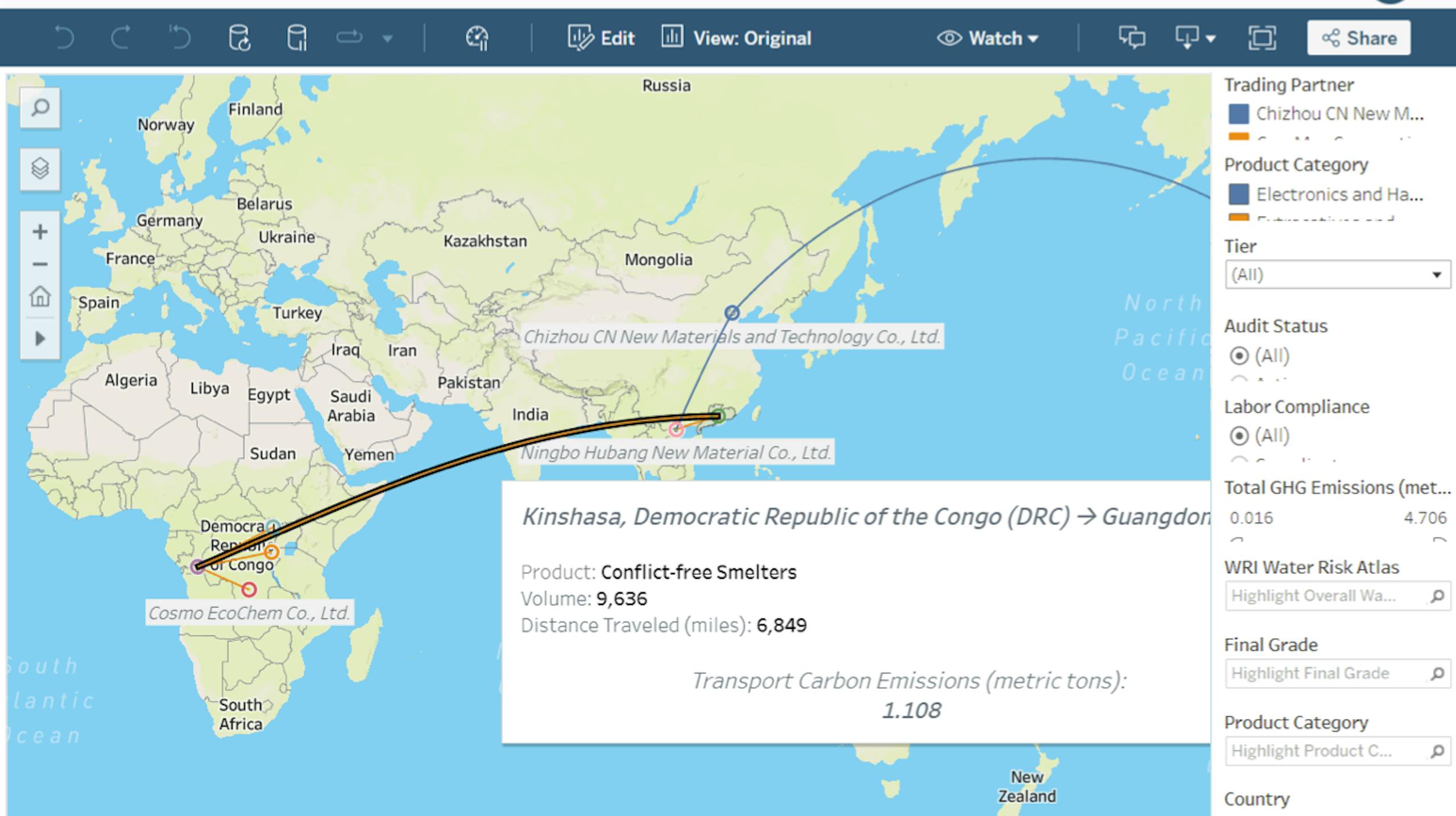

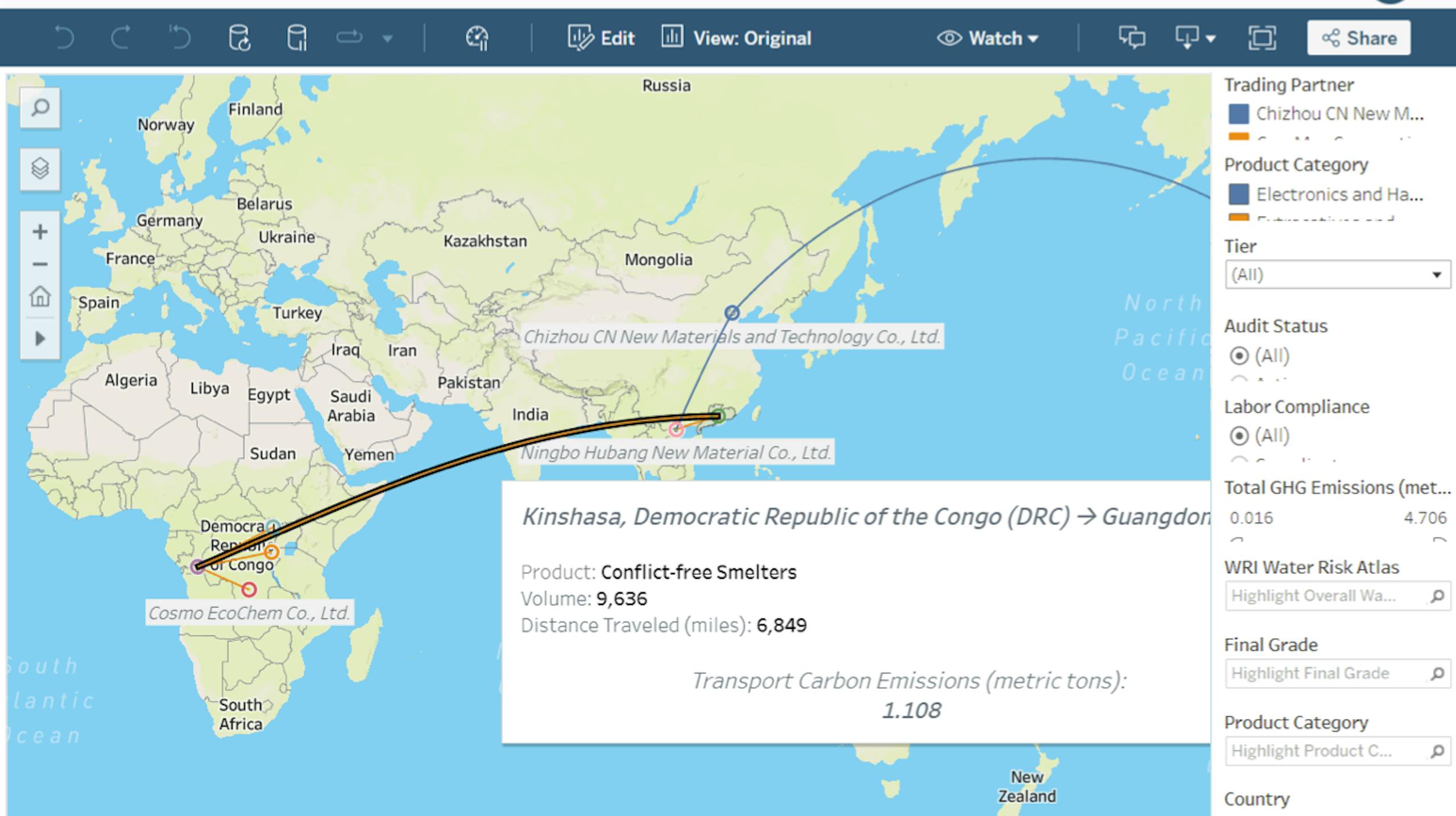

Visualize and Trace Risk Management

Thanks to partners like Riskonnect, John’s organization has unprecedented visibility into their supply chain from Tier 1 to Tier N. They can trace routes, chain of custody, and more with a 360-degree perspective into supply chain relationships at the supplier, site, product, and program levels.

Enterprise Risk Management

Sourcing managers, project managers, and other employees across the organization can anticipate, assess, mitigate, and monitor various forms of risk to your organization. Dashboards, as seen below, help expose risk factors by combining and surfacing relevant information from various data sources across the enterprise. By connecting risks with other relevant data, the relationships and cumulative impact are better understood.

This dashboard combines spend amounts with risk levels, locations, supplier tier, and compliance certifications to comprehensively represent the enterprise risk profile. However, as each element is further explored, flexible processes and actions can be taken directly from the insights that are revealed.

End-to-End Supplier Relationship Management

Organizations often face challenges viewing and interacting with their supplier data due to siloed information systems, and legacy file management systems with limited search and collaboration features.

The Salesforce platform provides a flexible no-code approach to these challenges by providing a 360-degree view of an organization's supply inventory via advanced data analytics, artificial intelligence, and an open API architecture enabling data integration with vendor inventory systems.

Supply chain stakeholders can easily create fully-immersive dashboards summarizing their key performance indicators with an easy-to-use drag and drop interface and intuitive menus.

Meet John, a Supplier Account Manager

John is a Supplier Account Manager whose organization recently adopted Salesforce and implemented a new Supplier Relationship Management application. John’s organization previously used a solution to manage supplier relationships that relied heavily upon multiple stovepipe systems and spreadsheets. This solution required hours of manual data entry and hours of analysis to identify actionable insights.

John is excited to use the Salesforce platform to get a 360-degree view of his organization’s supply inventory as well as gauge the health of their relationships with the key suppliers in their value chain.

John begins his day on the Supplier Relationship Management (SRM) app’s homepage, checking inventory levels on common-use parts to ensure an adequate supply.

Visualize Relationship Management Metrics

The Relationship Status section of the SRM dashboard provides John with a detailed overview of the reliability of all suppliers in his value chain. Dynamic filters drill down to specific vendors and individual reliability factors, enabling John to make data-driven decisions for sourcing future parts orders while limiting risk.

Supplier Account Information at a Glance

John’s organization previously used disparate data systems and legacy applications with high levels of technical debt requiring frequent code patching and updates. Salesforce acts as an engagement layer, unifying siloed data through configurable low-code integration tools while providing process automation and artificial intelligence features.

Here, John can see unified data on the supplier account General Magnaplate and uses these features to dramatically reduce manual effort and aid in his decision-making. Based on General Magnaplate’s reliability index, John decides to place an order.

Easily Create Purchase Orders with No-Code Process Automation Tools

John’s organization was able to create a guided user experience workflow in minutes using a no-code process automation tool, minimizing manual data entry and guiding John through the purchase order process.

John selects General Magnaplate to fill a gap in his inventory and quickly and easily create a purchase order without needing to log into his ERP system. Salesforce serves as the engagement layer for John’s organization, surfacing all of its supply, purchasing, and financial information in a secure interface, providing a 360-degree view of their data.

To get started, John clicks the “Create Purchase Order” button in his highlights panel.

Enable Mobile Collaboration with Slack

John uses Slack to collaborate with his program manager, David, who is often on the road and working from his mobile device. Once John submits the purchase order, David receives an instant notification directly in slack in his account management channel, with a message from John to review it.

David can respond to John’s message, view the purchase order details, and access the record in Salesforce from within Slack - all thanks to an integration that was set up in minutes with clicks, not code.

Guided Scorecard Creation

After the arrival of the parts shipment, John uses a guided experience user tool to score the supplier across key reliability impact areas, enriching the scorecard database and providing actionable to inform the supplier relationship selection process - all from within the Salesforce Platform. These scorecard metrics are surfaced in intuitive analytic dashboards, providing actionable data for informing supplier selection and purchasing decisions while limiting risk.

Access Supplier Account Insight On the Go

Salesforce Mobile puts the power of the Salesforce platform in John and David’s hands while on the go. They’re able to access supplier account details, contacts, open action items, and related activity history. Supplier inspections and audits are now much more efficient via the mobile application, which provides collaboration, image file uploading, navigation, and even voice-to-text for instantaneous updates to the inspection.

Visualize and Trace Risk Management

Thanks to partners like Riskonnect, John’s organization has unprecedented visibility into their supply chain from Tier 1 to Tier N. They can trace routes, chain of custody, and more with a 360-degree perspective into supply chain relationships at the supplier, site, product, and program levels.

Enterprise Risk Management

Sourcing managers, project managers, and other employees across the organization can anticipate, assess, mitigate, and monitor various forms of risk to your organization. Dashboards, as seen below, help expose risk factors by combining and surfacing relevant information from various data sources across the enterprise. By connecting risks with other relevant data, the relationships and cumulative impact are better understood.

This dashboard combines spend amounts with risk levels, locations, supplier tier, and compliance certifications to comprehensively represent the enterprise risk profile. However, as each element is further explored, flexible processes and actions can be taken directly from the insights that are revealed.